Working on construction sites involves unique challenges and risks. Among the various hazards you might encounter, electrical dangers often present the most severe threats. Adhering to an electrical safety checklist is essential to ensure your well-being and the safety of those around you.

Understanding the fundamentals of electrical safety helps protect you from potential accidents. From ensuring equipment is in good condition to maintaining safety protocols, taking proactive measures can significantly reduce the risk of electrical incidents. It’s crucial to be aware of the specific dangers associated with the tools and machinery you operate.

Staying informed about electrical safety practices isn’t just about following rules—it’s about saving lives. By integrating these practices into your daily routine, you design a safer workplace for everyone on-site.

Understanding Electrical Safety

Electrical safety is crucial in construction to prevent accidents and injuries. Workers must be aware of the fundamentals of electricity, recognise common electrical hazards, and understand how electric currents affect the human body. Awareness and proper safety measures can significantly reduce risks on site.

Basics of Electricity

Electricity is the flow of electric current through conductors, such as wires or cables, and is essential in powering tools and machinery. To ensure safety, you should understand the components that make up an electrical system, including conductors, insulators, and circuits. Conductors allow the flow of electricity, while insulators block it, providing protection.

Awareness of voltage, current, and resistance is important. Voltage is the force driving the electric current, while resistance opposes it. A strong grasp of these basics helps manage equipment safely and prevent incidents related to electrical faults or improper usage.

Common Electrical Hazards

Recognising electrical hazards is key to preventing accidents. Electric shock, electrocution, and fires can occur if proper precautions are not taken. Faulty wiring, damaged insulation, and overloaded circuits are potential risks in construction sites.

Arc flash, a dangerous electrical explosion, can cause severe thermal burns and injuries. It is vital to adhere to safety protocols and use personal protective equipment (PPE). Being vigilant and regularly inspecting electrical equipment reduces the likelihood of encountering such hazards.

Effects of Electric Current on the Human Body

Electric current can have dangerous effects on the human body. Even a small current can interfere with muscle control, potentially leading to falls or other injuries. Higher currents can result in serious damage, including deep burns, or even death.

Electric shock occurs if you come into contact with a live conductor. The severity of an electric shock is determined by factors such as the current’s strength and the duration of exposure. Recognising these dangers and using appropriate safety measures is crucial for protecting yourself and your colleagues.

Personal Protective Equipment (PPE)

Understanding the role of Personal Protective Equipment (PPE) in electrical work is critical for ensuring safety. Proper gear not only reduces the risk of injuries, such as arc flash and thermal burns, but also requires correct usage and consistent maintenance to remain effective.

Types of PPE for Electrical Work

Various types of PPE are essential for electrical work. Insulated gloves, for example, protect your hands from electric shocks. Wear arc-rated clothing to provide protection against arc flashes and minimise the impact of thermal burns. Use face shields and goggles to protect the eyes and face from potential hazards. Safety helmets are crucial to safeguard against falling objects and accidental bumps.

Footwear is another critical component. Ensure you wear boots with non-conductive soles to prevent electrical shock. Each type of PPE is designed to address specific hazards, so ensure your equipment aligns with the types of risks encountered in your work environment.

Correct Usage of PPE

Using PPE correctly starts with selecting the right equipment for each task. Fit is crucial; gloves and clothing must be the correct size to provide full protection. If gloves are too loose, they can slip off or snag. Clothing should fully cover arms and legs to prevent exposure to hazards.

Before each use, inspect all equipment for damage. Even minor tears or wear can significantly reduce effectiveness. Make certain face shields and helmets are properly secured and adjusted for a snug fit. Never modify PPE as alterations can compromise its protective qualities.

Maintenance of PPE

Regular maintenance of PPE is vital to ensure its long-lasting effectiveness. Clean PPE regularly following manufacturer’s instructions. Insulated gloves require frequent checks for punctures or tears. Turn them inside out to inspect seams carefully.

Store PPE in a clean, dry environment to prevent deterioration. Avoid exposure to direct sunlight, chemicals, or extreme temperatures, as they can weaken materials. Establish a routine for replacing equipment, especially when wear and tear become evident. Ensure any repairs are conducted according to professional standards to maintain safety levels.

Safe Handling of Electrical Equipment

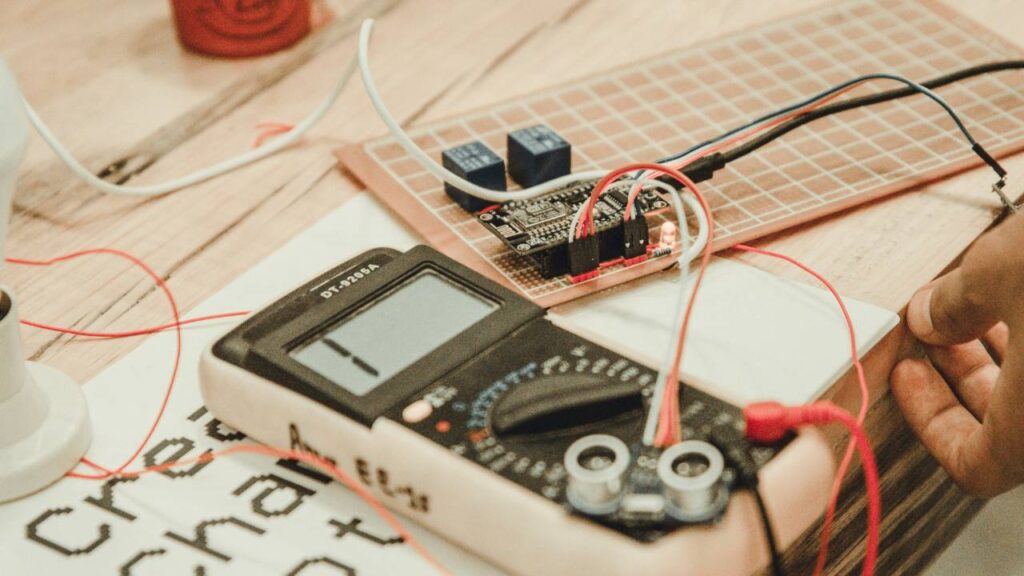

Ensuring safe handling of electrical tools and equipment is vital to prevent accidents on the construction site. Paying attention to inspection, correct use of extension cords, and regular maintenance can significantly enhance workplace safety.

Pre-use Checks for Electrical Tools

Before using any electrical tools, thorough inspection is necessary. Look for visible signs of wear or damage such as frayed wires or cracked casings. Ensure that tools are compatible with the power sources available on site. Verify that circuit breakers or residual current devices (RCDs) are in place and functioning properly.

Remember, regular checks can help identify potential hazards early. Companies like Electrical Safety Training in Ireland emphasise the importance of these checks, equipping workers with the knowledge to identify and mitigate risks effectively. Always disconnect equipment from the power source before inspecting internal components to reduce shock risk.

Proper Use of Extension Cords and Flexible Cables

When using extension cords and flexible cables, select ones designed for construction environments. Heavy-duty cords with appropriate insulation are crucial for safety. Avoid overloading cords beyond their specified ratings, which can lead to overheating and potential fires. Route cords away from sharp edges, water, or areas with heavy foot traffic to prevent damage or tripping hazards.

Do not coil or knot cords, as this can lead to overheating. Label and regularly check cords for any signs of damage. It’s essential to use ground-fault circuit interrupters (GFCIs) to provide protection against electrical shock and ensure compliance with safety standards.

Maintenance of Electrical Tools

Routine maintenance ensures the longevity and safety of electrical tools. Schedule regular servicing by qualified professionals to inspect, clean, and repair tools. Replace worn-out parts promptly to prevent malfunction. Maintain a log of all maintenance activities to track tool conditions and service history.

Encourage workers to report any issues with tools immediately. Storing equipment properly when not in use reduces the risk of accidental damage. Proper maintenance not only enhances efficiency but also decreases the likelihood of workplace accidents, making it an indispensable practice for any construction site.

Electrical Installation and Inspections

Ensuring the safety and reliability of electrical installations and regular inspections is vital at construction sites. Proper procedures minimise risks and hazards while maximising operational efficiency. Conscientious planning and execution lay the groundwork for safe and efficient electrical activities on site.

Setting Up Electrical Installations

Before beginning, thorough planning should consider site requirements, risk assessments, and layout. It is essential to ensure that all electrical installations comply with local standards and regulations. This involves the use of approved materials and equipment rated for construction environments. Installing effective earthing and bonding minimises potential electric shock risks.

You should ensure ample access and working space surrounding electrical equipment. This facilitates ease of maintenance and provides a buffer to prevent accidental contact. Mark access routes clearly to avoid obstruction. Installing warning signs should communicate present electrical hazards effectively and contribute to heightened on-site awareness.

Regular Inspections and Checks

Routine inspections are crucial to maintaining the integrity and safety of electrical systems. Conduct preliminary inspections before activating any electrical installations. Identify any potential faults or hazards that could compromise safety. Implement a regular inspection schedule to catch issues like wear and tear or equipment degradation early on.

Ensure inspectors are qualified to assess installations accurately. This enhances their ability to detect potential risks effectively. Records of all inspections, findings, and corrective actions should be maintained meticulously. These records support ongoing safety measures and compliance with legal requirements. Regular testing and replacement of worn-out components maintain the system’s safety.

Identifying and Labelling Electrical Circuits

Correct identification and labelling of electrical circuits prevents accidental outages and expedites troubleshooting. Each circuit should be clearly marked, specifying its function and areas it serves. Labels must be durable, easy to read, and often should be placed at key points accessible to users or maintenance personnel.

Accurately mapping circuit layouts and connections informs safe handling during electrical work. This promotes precise and safe alterations or repairs when needed. Colour codes and symbols further improve the clarity of circuit identification. Encourage all personnel to adhere to documented procedures and labels to maintain safety standards.

Working Practices for Construction Workers

Safety in construction sites requires strict adherence to specific practices when dealing with electrical hazards. Maintaining safe distances, handling equipment cautiously, and avoiding exposure to hazards are crucial to ensuring your safety.

Safe Distances and Access around Electrical Equipment

Maintaining safe distances around electrical equipment is vital for preventing accidents. Ensure that you keep a minimum distance of three metres from live electrical installations. Adequate barriers and warning signs should always be present, restricting unauthorised personnel access.

Reviewing and familiarising yourself with site-specific zoning regulations is necessary. It helps you identify hazardous areas where access may be restricted. Always respect these boundaries, ensuring you and your colleagues remain safe. Mindful adherence to these guidelines reduces the likelihood of accidents, enhancing safety on site.

Handling Live Circuits and De-energized Equipment

When handling live circuits, wear appropriate personal protective equipment (PPE), such as insulated gloves and safety footwear, to minimise risk. De-energise equipment whenever possible, using lockout/tagout procedures to ensure it remains in a safe state during maintenance.

Verify the absence of voltage using certified testing devices before beginning any work. Clear communication among team members about the status of equipment—whether energised or de-energised—is essential for avoiding misunderstandings. Adopting methodical practices in working with electrical systems ensures that safety remains the top priority.

Avoiding Hazards with Overhead Power Lines

Working near overhead power lines presents significant risks, and it is crucial to avoid these hazards. Always remain alert to your surroundings; identify all overhead lines before commencing work. Adhere to safe clearance distances which should be confirmed based on voltage levels with local regulations.

It is important never to work directly below or near overhead power lines with any extended material or machinery. If work must be done near these lines, mitigate risks by coordinating with the utility company for protective measures. Consistent vigilance and adherence to protocols effectively protect you from dangerous contact with live wires.

Electrical Safety Devices

In construction work, electrical safety devices are crucial for preventing accidents and ensuring safe operations. Always ensure these devices are properly installed and maintained to mitigate risks.

Circuit Breakers and Fuses

Circuit breakers and fuses are essential components in managing electrical circuits. They act as safeguards against overcurrent by interrupting the flow of electricity when an overload or fault is detected.

Circuit breakers can be reset manually, unlike fuses, which need replacement once activated. Installing these devices correctly ensures excess current does not damage equipment or create fire hazards. Ensuring they match the circuit’s load capacity is also vital to preventing unnecessary trips, which can disrupt construction activities.

Regular inspections of circuit breakers and fuses are necessary. Look for signs of wear, corrosion, or damage, which could compromise their effectiveness. In addition, understanding their ratings and compatibility with your existing electrical setup can prevent mishaps and promote safety.

Ground Fault Circuit Interrupters (GFCIs)

Ground Fault Circuit Interrupters (GFCIs) are designed to protect individuals from electric shocks. They cut off power when a ground fault is detected, reducing the risk of electric shock in damp or wet conditions often found on construction sites.

GFCIs are crucial when using portable equipment and during temporary electrical setups. They should be installed in areas prone to moisture, such as bathrooms or outdoor locations. Proper testing of GFCIs, using the test button, ensures they function correctly.

You must ensure routine maintenance and testing of GFCIs to avoid malfunction. Keeping them clean and clear of debris helps maintain their efficiency. GFCIs are a critical component in comprehensive electrical safety and should never be overlooked.

Risk Assessment and Safety Protocols

Risk assessment and safety protocols are essential for electrical safety in construction. Understanding these elements helps prevent injuries, minimise property damage, and ensure a seamless workflow on-site.

Creating a Safety Checklist for Electrical Work

A comprehensive safety checklist is crucial for identifying and mitigating electrical hazards. Start by assessing potential risks specific to your construction site. This includes evaluating equipment, power sources, and environmental conditions. Staying current with regulatory changes ensures that your safety checklist reflects the most up-to-date compliance requirements and industry standards. Implementing lockout/tagout in construction is vital to prevent accidental energisation of electrical systems during maintenance. Keep the checklist updated with current safety standards and protocols. Regular training and drills should reinforce these practices, ensuring that every team member understands the necessary precautions.

Responding to Electrical Accidents

Handling electrical accidents swiftly and correctly can significantly reduce harm. First, cut power immediately to the affected area and secure the surroundings to prevent further exposure to risks. Appropriate first aid, including CPR, may be necessary if someone is injured. Always have emergency contact numbers and a reliable method of communication readily available. Ensure all incident details are recorded accurately for future reference and potential improvements in safety protocols. Encourage reports of near misses to identify areas needing attention before actual accidents occur.

Minimising Risk of Property Damage

Preventive measures are key in protecting property from electrical damage. Regular inspections and maintenance of electrical systems identify potential issues before they cause harm. Use proper materials and installation techniques to contain arc blasts and other destructive incidents. Invest in quality surge protection devices to protect equipment from unexpected power surges. Encourage safe practices, such as keeping combustible materials away from electrical sources and maintaining clear access to electrical panels. These actions contribute to safeguarding both personnel and property and maintaining a secure construction site.

Conclusion

Adhering to an electrical safety checklist is crucial for the protection of construction workers. Implementing these measures helps create a safer work environment, reducing the risk of accidents and injuries.

Regularly reviewing and updating your safety protocols is essential. It ensures they align with the latest regulations and technologies. By prioritising these measures, you not only safeguard your workforce but also strengthen your business for the future.

Encourage open communication about safety concerns among team members. This fosters a culture of accountability and vigilance, further enhancing workplace safety on construction sites.